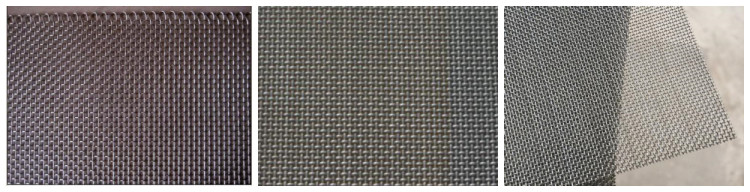

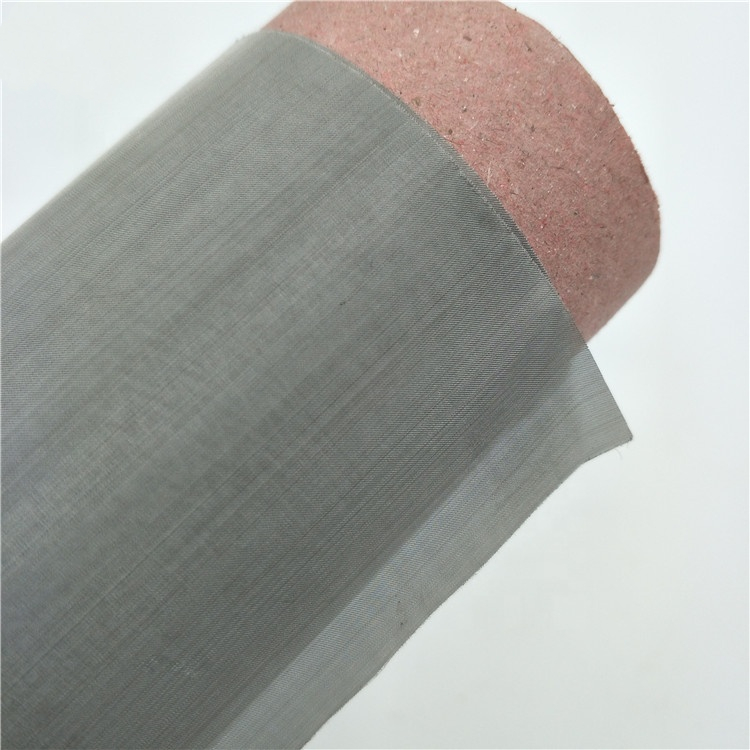

Pure molybdenum weave wire mesh

$99.00 $36.00

Pure molybdenum wire mesh

Material: Pure molybdenum

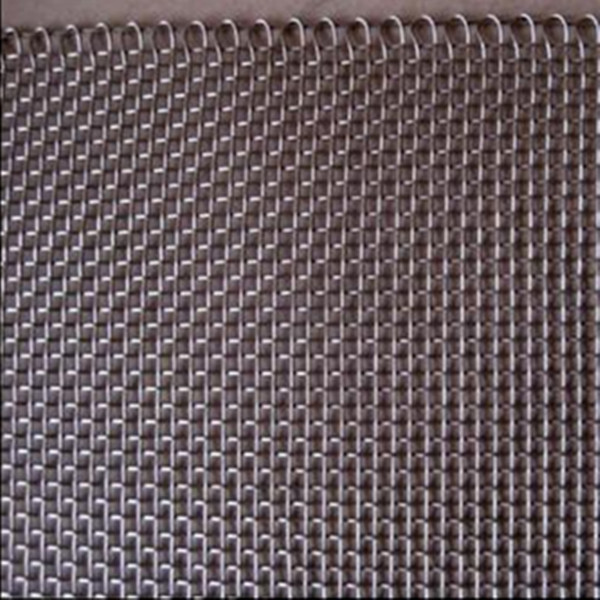

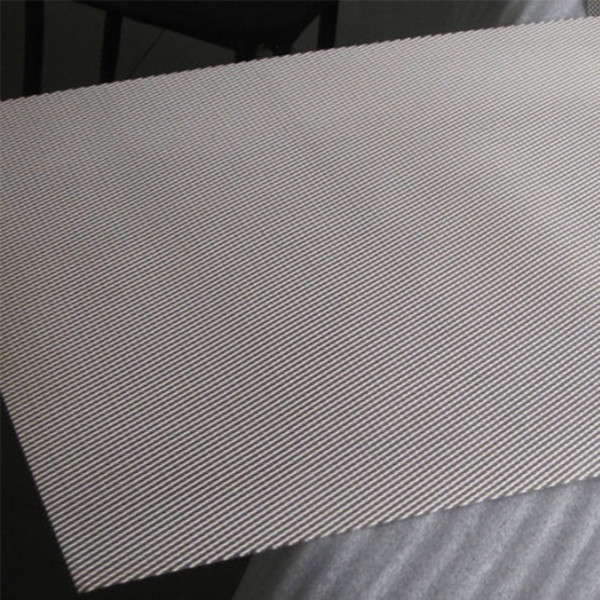

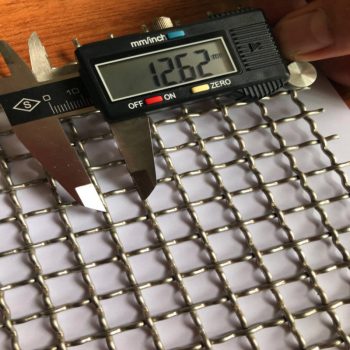

Mesh: 20 mesh x 20 mesh

Wire diameter :0.30 mm

Aperture(mm): 0.97 0mm

Description

Description of Pure molybdenum weave wire mesh

Grade: MO-1/MoLa

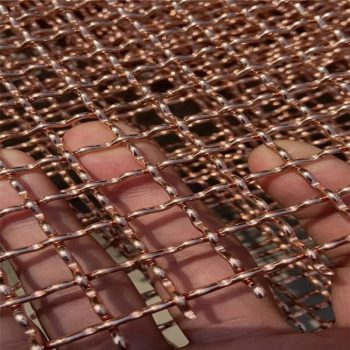

Surface: 1. Bright pure molybdenum wire Molybdenum content ≥99.95%; 2. Black pure molybdenum wire (with graphite emulsion coating on the surface); 3. Molybdenum-niobium alloy MO99.6%; antimony content 0.3%

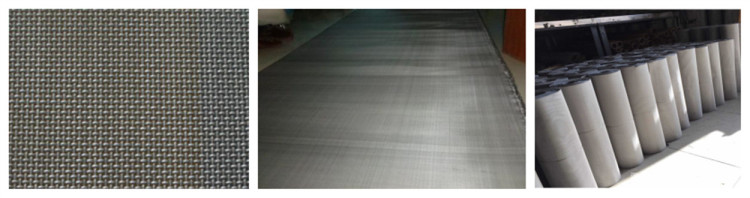

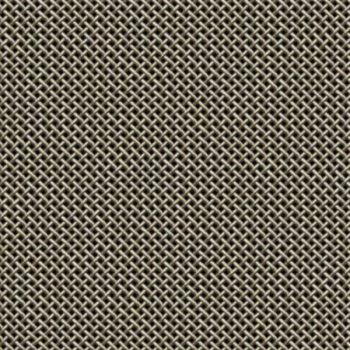

Applicable temperature: 1100°C,Melting point: 2610°C,Process: plain weave,Hole shape: square,Aperture: 0.02mm-50mm,Mesh: 0.3 mesh – 400 mesh,Width: 10mm-2000mm,Shape classification: It can be cut into circles, rectangles, ovals, etc. according to actual needs.

Uses of Pure molybdenum weave wire mesh:

Molybdenum mesh has excellent high temperature resistance, mainly used for soft magnetic sintering and supporting molybdenum box. In the strong magnetic sintering, the vacuum furnace is used as a pallet, and the infiltration heat treatment equipment is fully automated, so there is a high requirement for the flatness and the braiding strength of the molybdenum mesh. The molybdenum-niobium alloy can effectively enhance the surface strength of the molybdenum mesh, so that it can have good flatness after leveling treatment

Advantages of Pure molybdenum weave wire mesh:

At present, many Japanese companies purchase the company’s molybdenum net for the sintering of new magnets. We have accumulated a large amount of production data and perfected the quality control system. And according to customer feedback, product improvement, improve the service life of molybdenum net.

Working style: continuous work

Variety products: Molybdenum mesh is heated in a vacuum furnace, using a fully automatic sintering device. Each batch of strong magnetic sintering is completed. The molybdenum mesh needs to be taken out with the sinter, which causes oxidation. The surface of the black molybdenum mesh contains a graphite emulsion coating. Protecting the molybdenum wire substrate slows oxidation and increases service life.

Improved process:

molybdenum mesh is mainly caused by edge oxide breakage, so the use of double wire weaving of molybdenum mesh at the edge to improve the edge strength of molybdenum wire mesh can also improve the service life of molybdenum mesh. According to the actual production needs, the edge of the molybdenum mesh can be wrapped with molybdenum foil, which not only solves the problem of silk burrs at the edge of the molybdenum mesh, but also improves the number of times of use, thereby reducing the cost of use

Reviews

There are no reviews yet.