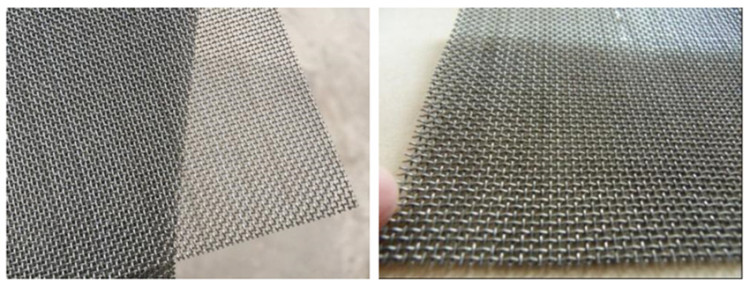

Molybdenum Sintered Wire Mesh

$88.00 $36.00

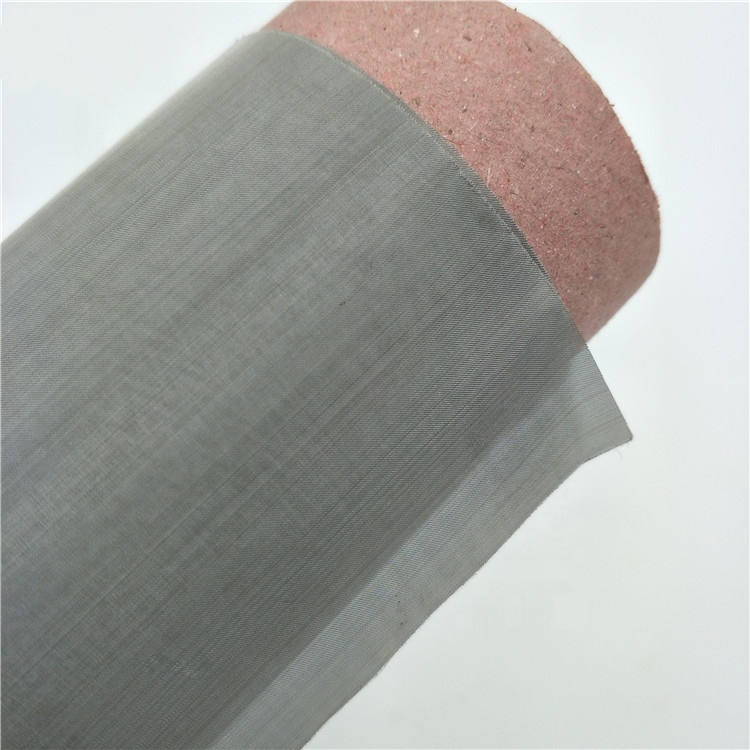

Molybdenum Sintered Wire Mesh

Material: Molybdenum Wire

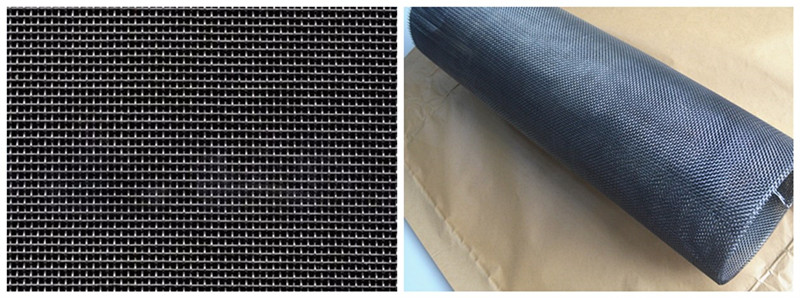

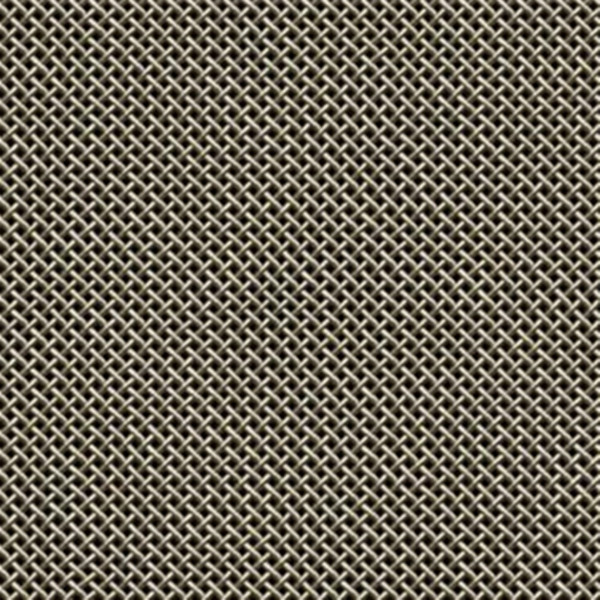

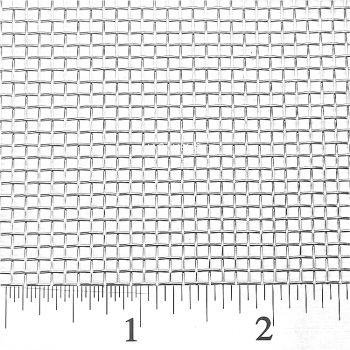

Mesh: 16 x 16 mesh

Wire diameter: 0.4 mm

Opening: 1.188 mm

Feature: High melting point, High-density

Description

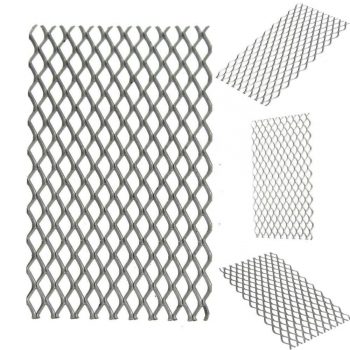

Molybdenum Wire mesh Sintered Wire Mesh

Permanent magnet materials are also known as “hard magnetic materials.”A material that maintains a constant magnetic property upon magnetization. It has a wide hysteresis loop, high coercivity and hysteresis loop hysteresis loop high remanence. In practice, the permanent magnet material operates in the second quadrant demagnetization portion of the deep magnetic saturation and hysteresis loop after magnetization.

Materials of Molybdenum Sintered Wire Mesh

1.Specification of Molybdenum Sintered Wire Mesh

| Mesh/Inch | Wire diameter | Aperture (mm) |

Mesh/Inch | Wire diameter | Aperture (mm) |

| 1 | 2.03 | 22.37 | 30 | 0.25 | 0.596 |

| 2 | 1.8 | 10.90 | 40 | 0.21 | 0.425 |

| 4 | 1.2 | 5.15 | 50 | 0.19 | 0.318 |

| 6 | 0.8 | 3.433 | 100 | 0.10 | 0.154 |

| 8 | 0.60 | 2.575 | 120 | 0.08 | 0.132 |

| 10 | 0.55 | 1.990 | 150 | 0.065 | 0.104 |

| 12 | 0.50 | 1.616 | 180 | 0.053 | 0.088 |

| 14 | 0.45 | 0.362 | 200 | 0.053 | 0.074 |

| 16 | 0.4 | 1.188 | 250 | 0.04 | 0.061 |

| 18 | 0.35 | 1.060 | 300 | 0.035 | 0.049 |

| 20 | 0.3 | 0.970 | / | / | / |

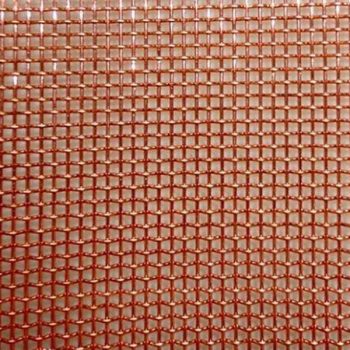

2, Advantages of Molybdenum Sintered Wire Mesh

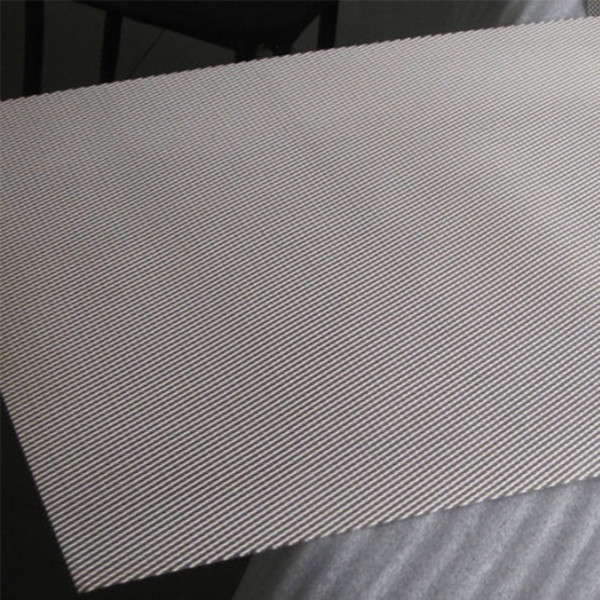

The molybdenum mesh is characterized by high temperature resistance, high hardness, and low deformation in a high temperature environment, and the mesh woven structure has excellent gas permeability, so that the rare earth strong magnetic material has good support and temperature uniformity in the vacuum furnace sintering.

In the sintering process of the permanent magnet material of the vacuum furnace, the working environment temperature of the molybdenum mesh is 1100 ° C, and the working mode is continuous operation.

Compared with the tungsten mesh,

the same specification size molybdenum mesh has lower weight and lower raw material cost. The molybdenum mesh meets the design requirements of working strength in a high temperature environment, and has a cost advantage.

3. Industrial Molybdenum Wire Netting For Radiation Shield

| Delivery condition | Specification | Tolerance | Thickness | Roughness | ||

| Diameter | Height | Diameter | Hight | |||

| Sintering | 10-500 | 10-750 | ±3.0 | ±3.0 | 8~20 | / |

| Final Finished | 10-450 | 10-550 | ±0.5 | ±1.0 | 7~18 | ≤3.2 |

Reviews

There are no reviews yet.