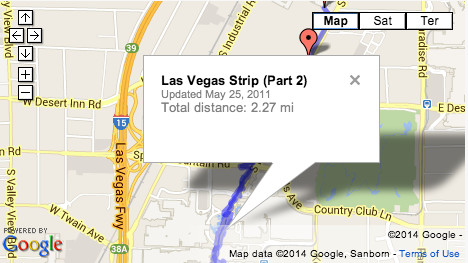

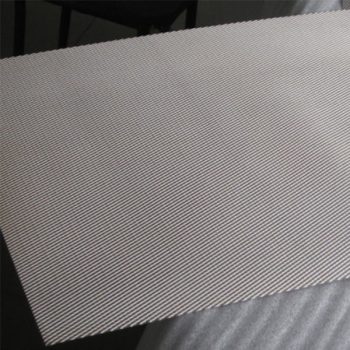

Platinum plated titanium anode mesh

$96.00 $66.00

Platinum plated Titanium anode

Material:Titanium Ti TA1

Sheet Thickness:0.5 mm

Opening: 10*25 mm

Current density: 8000 A/M2

Description

Platinum plated titanium anode mesh

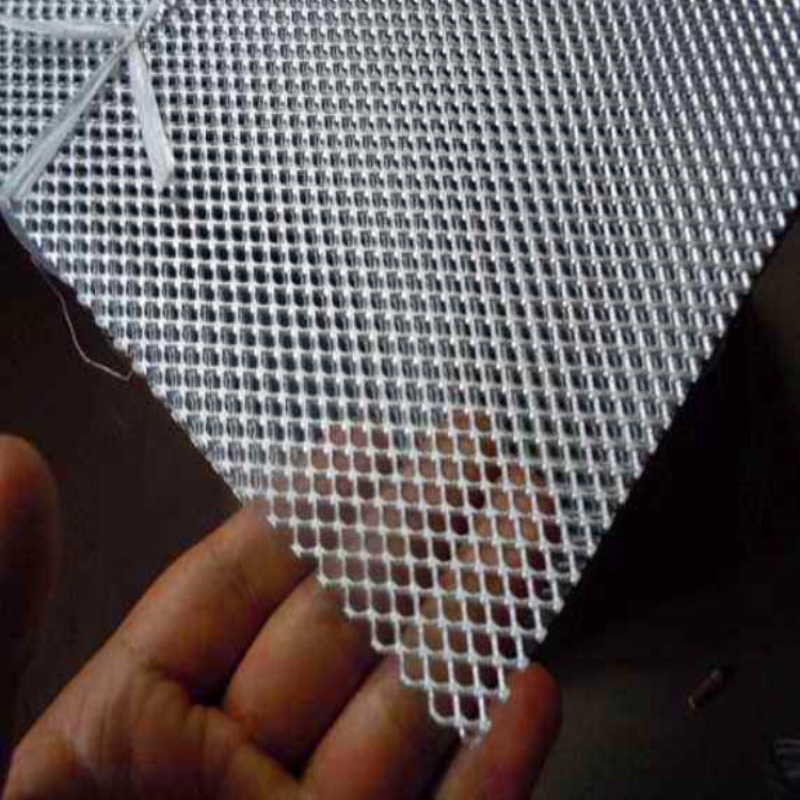

Platinum anode: titanium as the substrate. The surface is plated with precious

metal platinumand the thickness of the plating layer is generally 1-5um.

Titanium mesh mesh specifications for platinum are generally

12.5×4.5mm 6×3mm and 4.5×2.5mm

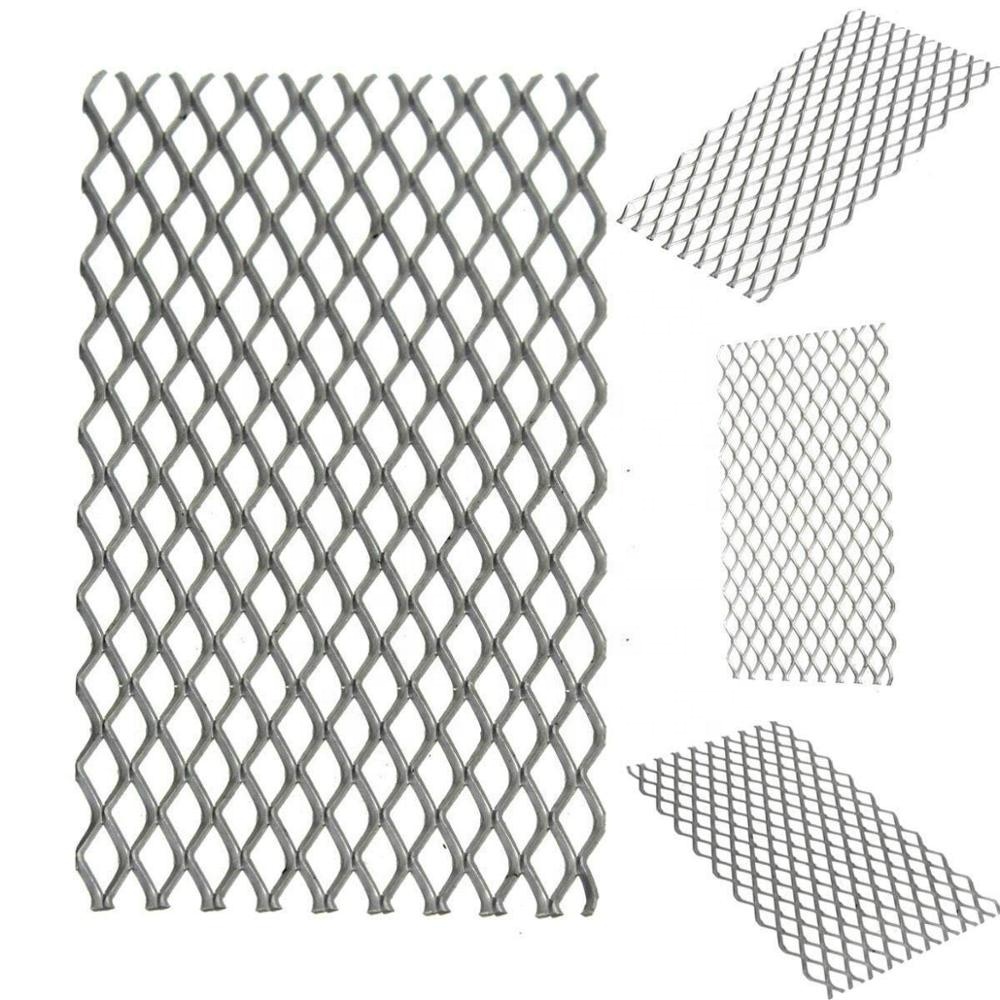

Platinum-titanium-insoluble anodes

The titanium-based anodes have mesh plate rod filament andtube shapes. The standard platinum layer has a thickness of 2-5 μm. Under higher requirements

the thickness of the platinum layer can reach 20 μm. The service life of the platinized titanium anodedepends on the current density (current density) of the working medium (electrolyte) and the anode.

The current density should not exceed 75A/dm2. Below this value the wear of the platinum layer is small and the anode lifetime can also be estimated. As a rule of thumb the platinum layer wears in the order of

1-4 grams per million amp hours in a fluorine-free chromium plating bath. When the current density is higher than 75A/dm2 or using a fluorine-containing electrolyte we recommend the use of a platinum-plated

tantalum anode (see Platinum-plated tantalum anode).

| Matrix metal: | Gr1、Gr2 | Coated metal: | Pt+X |

| Current density range: | <5000A/M2 | The thickness of the platinum | 1~5um |

| Electrode shape: | Net pipe rod board | Board temperature range: | <80℃ |

| Fluoride ion content | <50mg/L | Ph | 1-12 |

Advantages of Platinum plated titanium anode mesh

High corrosion resistance

High current efficiency

Long working life

After the electrodes lose their activity the matrix can be repaired

High current density high production efficiency

The weight of the electrode is light

Reviews

There are no reviews yet.